Raku

Raku must be one of the most fun techniques used in ceramics. Almost instant glazing, that can be unpredictable but so often gives fabulous results that are dependent on the whims of the firing temperature and reduction process. These can be enhanced and controlled to some degree by forms, texture and application of glaze. For me Raku days are a day off to enjoy myself away from my production of domestic and comercial wares.

Reduction

For reduction I usually use a combination of wood chips and sawdust, around fifty fifty, I have found that too much sawdust can result in a rather dull finish to the glaze surface. The combination of wood chip allowes more oxygen in the mix that easily ignites creating a good reduction environment and a bright glaze.

Pattern Making

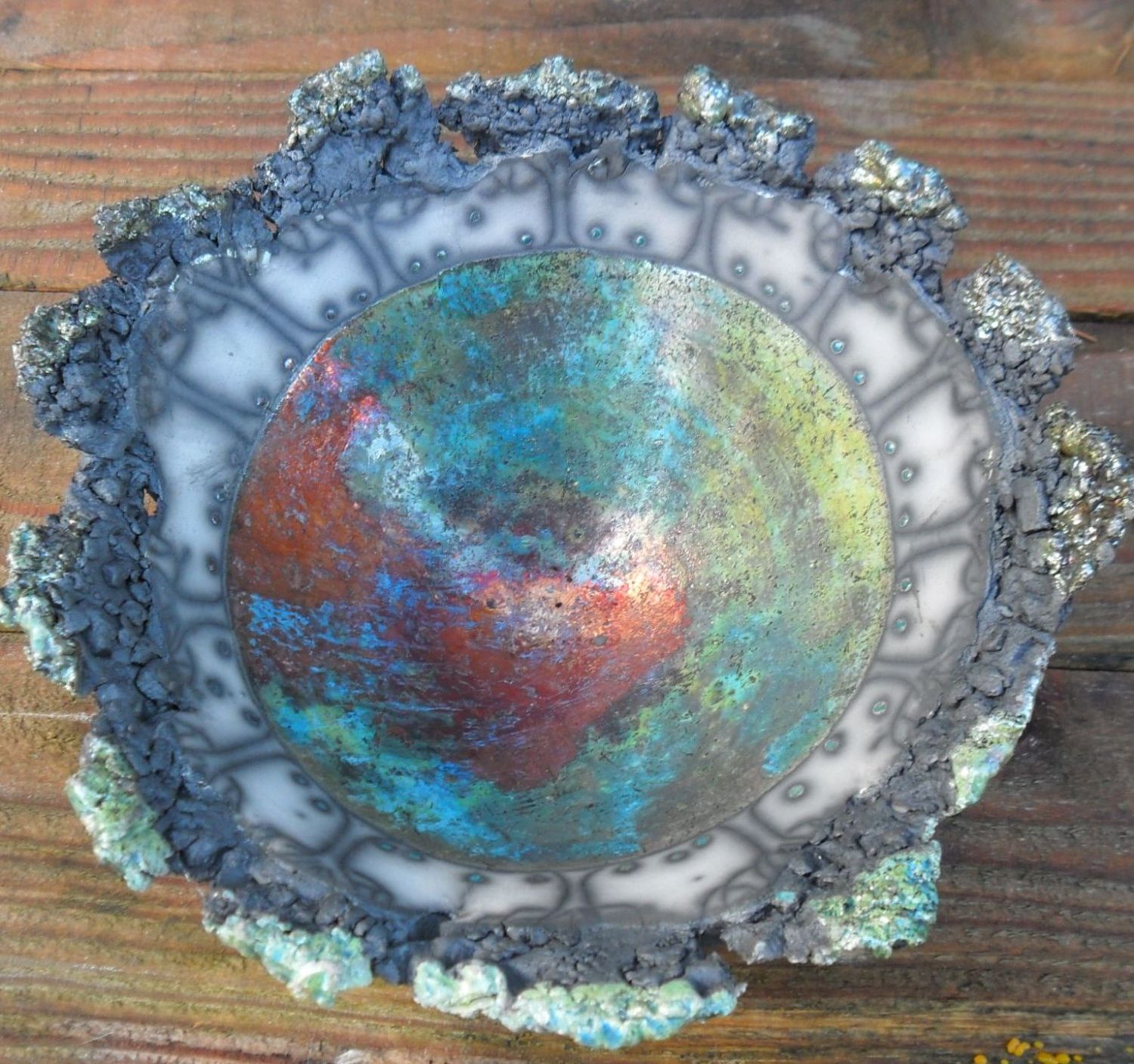

The image on the right was created by incising into the leather hard pot coupled the use of a drill bit to create circular recesses. Before the pot is bisque fired copper carbonate is run into the surface patterns, any excess is wiped off the surface using a damp sponge. Once fired the copper is fixed and will enhance the glaze. The same process is used when applying the glaze coupled with different stencils used to stipple further surface decoration.